JPM RE-INVENTS CAB SHIELD GUARDS

The finding was as follows:

- Many users never use the guards

- They increase the front surface of the body and therefore CO2 emissions

- They are not optimized from a functional standpoint (impossible to strap down, bad location)

- They get stuck under low clearances

With the new version of the aluminum tipper, JPM has removed the "guards" from its cab shields and attempted to find a solution more suited to the needs of its users.

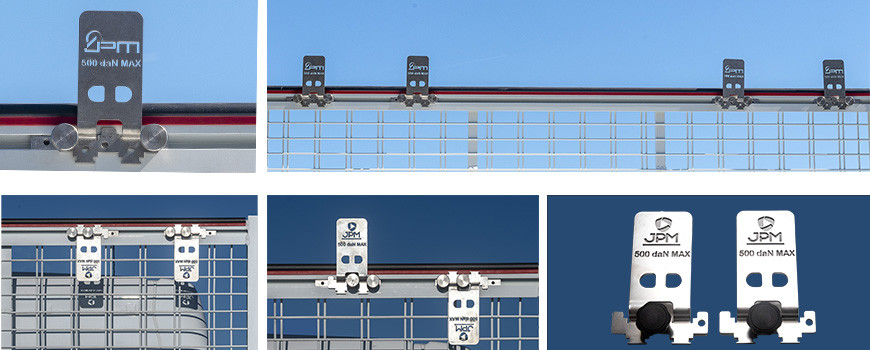

Since not all dump truck owners use them, JPM first made them an option called load stops. They are in fact optimized guards. Indeed, load stops have many benefits:

- They can be moved to any location on the cab shield without tools

- They allow loads to be strapped down (500 daN of force)

- They can be returned if not used. Low clearances become easier.

- Each user adjusts the number of load stops they need on their cab shield.

JPM, in collaboration with tipper users, has made a part of the tipper functional and useful that everyone else had neglected. A user who wishes to do so has a "stop load" option to meet their needs, thus making their work more efficient and less cumbersome.