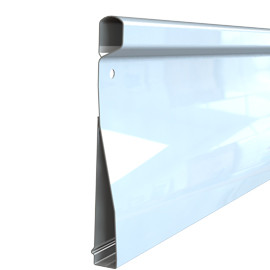

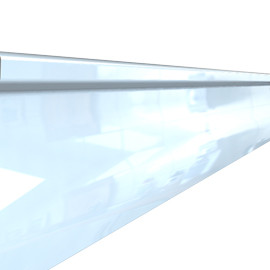

For our most common tipper lengths we use ZMA galvanised steel sheet: it is a standard hot galvanisation into which magnesium has been incorporated. It is this magnesium which makes it a much more effective galvanisation than a standard hot galvanisation. If there is an impact the steel sheet remains treated. It is the coating that is best adapted to aggressive environments: beside the sea or roads which have been salted. After controlled shot blasting (not destroying the GalvaZ), we apply

- a coat of primer - a thermosetting powder epoxy resin. It is a long life corrosion protection.

- a coat of paint: thermosetting powder polyester resin resistant to impacts and scratches.

That is a total minimum layer of 120 µm.