What is a dropside truck?

A dropside is a fixed loading platform which is generally very long. Access to loading is fast and easy on this type of body because it is accessible from 3 sides due to the sideboards and rear door which are fold-down and/or removable.

What are the uses of a dropside truck?

A vehicle fitted with a dropside is the ideal combo for:

- Providing transport for a work team: from 2 to 7 people depending whether the truck has a single or a double cab

- Transporting merchandise that is very long and/or irregular in shape and/or voluminous. In fact, because it is fixed, the bodywork dimensions may go up to the maximum authorised.

- Transporting pallets: widthwise (generally 2000 mm), 2 pallets can be placed side by side. They can be loaded/unloaded easily from the 3 sides of the dropside by a forklift truck.

- Delivering heavy goods.

The different types of dropside trucks

JPM offers 3 types of dropside:

- The aluminium dropside, wood platform

The all steel dropside

- The aluminium dropside

These 3 JPM dropsides have the following common characteristics

- Robustness due to:

o A front face welded to the dropside

o The use of bead welding which is the most resistant welding technique

o A rear pillar guaranteeing the rigidity of the assembly

o Boxing of the sideboards making them very resistant to deformation

- Practicality and ergonomics

o Removable rear pillars

o Fold-down and removable sideboards and rear door

o Possible addition of options such as a beam rack or a cover framework.

- Payload: it is optimised particularly due to aluminium models

H2/ Who are dropsides for?

Due to their great versatility, dropsides are used in very different sectors:

- Building: renderer, plasterer, scaffolder, carpenter, roofer, etc.

- Craftsmanship: ironworker, boilermaker, joiner, etc.

- Industry: pipe fitter, panel beater, etc.

- Transport: driver-delivery man, etc.

- Agriculture: beekeepers, etc.

- Local authorities

The advantages of the dropside truck

Ultimately all these trades have very different activities. It is therefore essential to customise the dropside depending on the specific needs of its user. Several accessories or options may complete this bodywork:

- Behind cab storage locker: this storage take small tools. It is possible to add to it shelves, a non-slip mat and burglar-proof doors.

- Beam rack: It is easily installed above the rear pillars. It facilitates loading and the transport of very long items. It can even be fitted with rollers so that you can slide equipment during loading

- Box under the tipper: These space-saving boxes placed under the tipper make it possible to store all small tools efficiently. Available in polyurethane and stainless steel, some models even specialise in the storage of a type of accessory like straps.

- Lashing rings: Positioned on the bottom of the dropside and/or on the cab protection, they guarantee that the load is secured correctly.

- Tarpaulin covering: it makes it possible to hide the goods transported and protect them from inclement weather.

- Step: it is installed on the door and/or sideboard and facilitates access to the dropside. This equipment is completed by a handle fixed on the cab protection.

- TRIVA Entreprise: bar used for coupling (with mixed hook) AND underrun protection

- Tail lift: installed at the back of the dropside. It facilitates loading/unloading and reduces effort during handling operations.

- Crane, jib crane, etc.

A customised dropside is more practical, more ergonomic and makes it possible to reduce difficulty and improve user safety. This is therefore a real advantage for increasing efficiency.

How should a dropside truck be chosen?

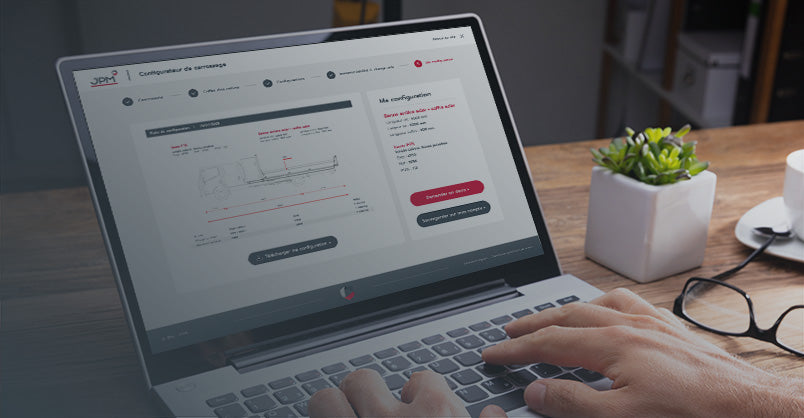

Choosing a dropside means choosing a body suitable for the vehicle AND for the professional activities. JPM will guide the choice using 2 tools:

- The bodywork configurator: this tool offers you dropside lengths compatible with the vehicle you have chosen or truck models technically suited to the length you need. Once you have made your selection, it will calculate the remaining payload.

- The decision-making tool: Depending on your trade it will suggest a certain number of accessories facilitating your work and thus enabling you to increase efficiency. You can purchase these options directly in the JPM Shop, the online JPM shop.

When you have made your choice, it is up to the JPM distributor network to take over. Located as close as possible to you, they will assemble the dropside and the chosen accessories and provide technical follow-up for the dropside. All steel and aluminium dropsides are guaranteed for 2 years and JPM offers a third year if you register your bodywork on the JPM website.

The JPM dropside is therefore a true work tool, designed for demanding applications and guaranteeing ease-of-use and performance every day.