Steel dropside RANGE 55

Which length on which chassis?

Perform the testThe strengths of the steel dropside

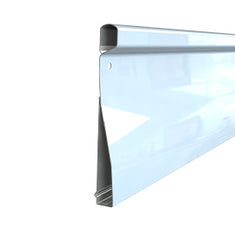

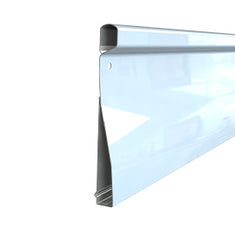

Front face welded to the platform Front face welded to the platform

Sideboard rigidity Sideboard rigidity

Seam welding Seam welding

Long life Long life

Finish resistant to impacts and scratches Finish resistant to impacts and scratches

Discreet, efficient ladder holder Discreet, efficient ladder holder

Prevention of impacts when opening the sideboards Prevention of impacts when opening the sideboards

Lashing on the outer frame of the platform Lashing on the outer frame of the platform

Large surface for stickers Large surface for stickers

Customisable bodywork Customisable bodywork

Bodywork you can maintain yourself Bodywork you can maintain yourself

Up to 5 years warranty Up to 5 years warranty