BODYWORK

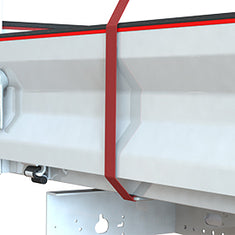

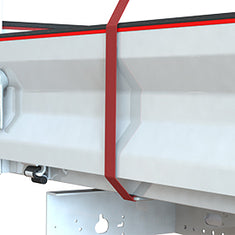

• Tipper platform in high quality aluminium sheet: 5083 H16 thickness 3.5 mm

• Side members in extruded box-sections, thickness 3 mm, height 120 or 140 mm (depending on length) and outer frames in box-sections, thickness 3.5 mm, under the load surface

• Sideboards in extruded aluminium profile, height 400 mm (385 mm interior), usable interior height 388.5 mm, double wall top and bottom, thickness 2.8 mm, single wall, thickness 3.5 mm in the centre, fold-down, removable, interchangeable (right/left)

• Locking handle incorporated into the thickness of the sideboards

• Front face, usable interior height 450 mm, double wall top and bottom, thickness 2.6 mm, single wall, thickness 3.5 mm in the centre

• Cab Protect with aluminium grille diameter 5 mm with frame in extruded profiles, removable and without top cap

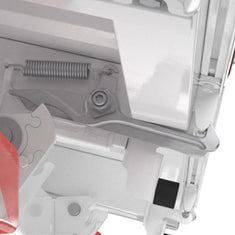

• Aluminium rear door, height 450 mm, double wall top and bottom, thickness 2.8 mm, single wall, thickness 3.5 mm in the centre, automatic opening by cam of 15° (doorway 520 mm)

• Rubber opening stops on sideboards and rear door

• Rear pillars in galvanised steel, thickness 3 mm, removable, with 12 mm tightening fixing bolt and conical fitting

• Polypropylene fender flares with supports in unwrought aluminium

• Approved aluminium side protection, black powder paint

• Nickel Zinc treated bolts (5 times more resistant than standard galvanising)

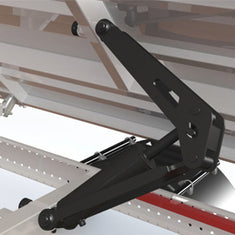

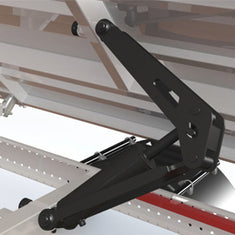

• Tipping on aluminium spherical bearings and forks, contact on elastomer

• Locking pins in Nickel Zinc treated steel with code (preventing any false manoeuvre)

• Outer frame adapted to lashing

• Short dumping overhang: 340 mm

SUBFRAME

• Aluminium profile tipper, thickness 4.5 to 12 mm

• Tipping by COMPASS CYLINDER (no overhang under the subframe)

• Rear tipping angle of 48° and laterally 45°

• Electrically driven pump unit, 12 or 24 volts depending on the vehicle

• 3-litre tank

• Hydraulic pressure 320 bars

• Wired remote control in cab

SAFETY

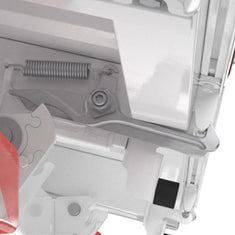

• Safety solenoid valve on cylinder

• Circuit breaker

• Safety stand

• Double safety device on the sideboard handles

• Double safety device on the upper door hinges

FINISH

• Shot blasting + 60 μm powder primer + 60 μm powder paint