Mixed aluminium rear tipper

Which length on which chassis?

Perform the testThe strengths of the mixed aluminium rear tipper

Robust Robust

Seam welding Seam welding

Ergonomic grip Ergonomic grip

Fuel savings Fuel savings

Long life Long life

OPTIMUM PAYLOAD OF JPM ALUMINIUM TIPPERS OPTIMUM PAYLOAD OF JPM ALUMINIUM TIPPERS

Tapered pillars Tapered pillars

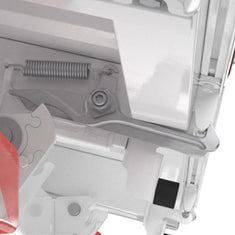

Door hinge Door hinge

Finish resistant to impacts and scratches Finish resistant to impacts and scratches

High dumping capacity High dumping capacity

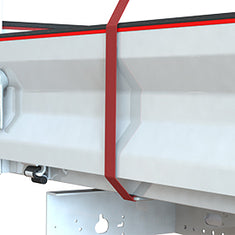

Aluminium side board with sealing lip Aluminium side board with sealing lip

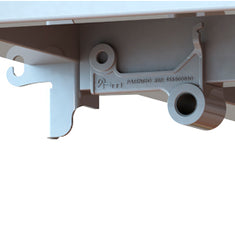

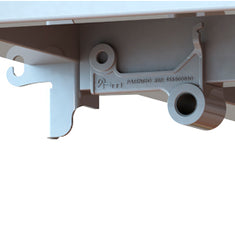

Discreet, efficient ladder holder Discreet, efficient ladder holder

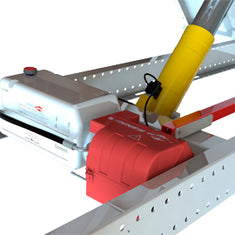

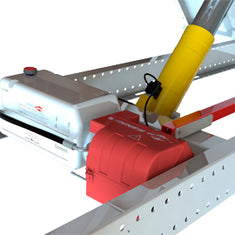

Optimised articulation Optimised articulation

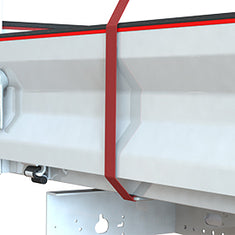

Possibility of lashing on outer frame Possibility of lashing on outer frame

No lubrification No lubrification

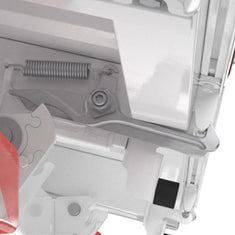

Reliability of door opening Reliability of door opening

Customisable bodywork Customisable bodywork

Bodywork you can maintain yourself Bodywork you can maintain yourself

Environmentally-friendly bodywork Environmentally-friendly bodywork

Up to 5 years warranty Up to 5 years warranty