BODYWORK

• MAX. load capacity: 3 T

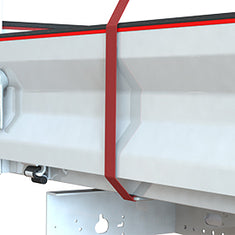

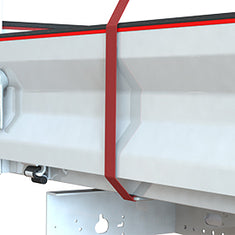

• Tipper platform in high quality aluminium sheet: 5083 H111 thickness 4 mm

• Longitudinal reinforcement spacers

• Sideboards in steel H350ZMA, height 350 mm, thickness 2 mm, fold-down, removable• Closing of embedded sideboards

• Front face, height 450 mm, thickness 2.8 mm

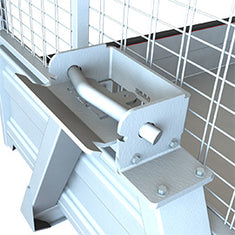

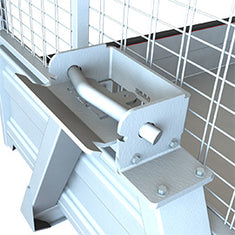

• Cab Protect in galvanised steel, with grille (4.5 mm section), removable and without top cap

• Rear door in steel H350ZMA, height 450 mm, thickness 2 mm, 2 leaves and bottom unhooking by manual unlocking

• Stops on sideboards and rear door

• Rear pillars in galvanised steel, thickness 3 mm, removable, with adjustable fixing bolt and conical fittings

• 2 rear rolls in aluminium fitted on self-lubricating ring (no greasing)

CRADLE

• Y-shaped frame rails, height 120 mm, thickness 8 mm

• Centre distance 1060

• Hook height 920 mm

• STEEL gripper axis diameter 30 welded on a steel pressed frame

bolted to the structure

• Exterior and interior locking

SAFETY

• Anti-theft device to be locked

FINISH

• Shot blasting + 60 μm powder primer + 60 μm powder paint