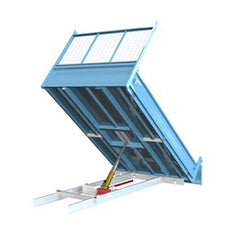

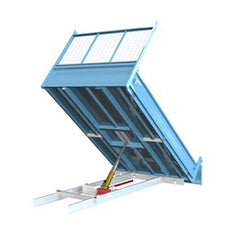

Steel rear tipper RANGE 75

Which length on which chassis?

Perform the testThe strengths of the rear tipper 75

Galvaz : the anti-corrosion treatment for steel tippers Galvaz : the anti-corrosion treatment for steel tippers

Tapered pillars Tapered pillars

Seam welding Seam welding

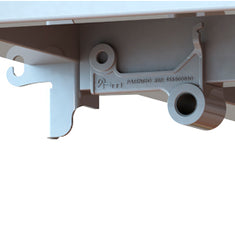

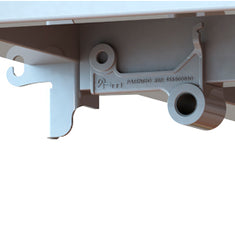

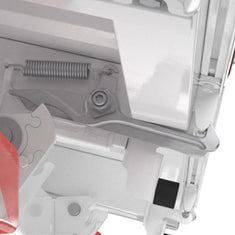

Door hinge Door hinge

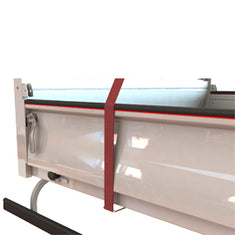

Sideboard with watertight lip Sideboard with watertight lip

No lubrification No lubrification

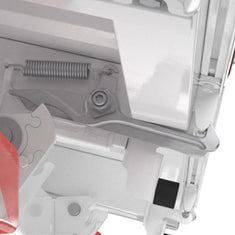

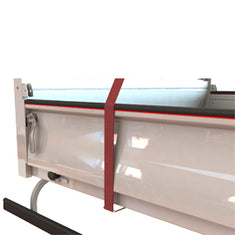

Prevention of impacts when opening the sideboards Prevention of impacts when opening the sideboards

Reliability of door opening Reliability of door opening

Large surface for stickers Large surface for stickers

Lashing on the outer frame Lashing on the outer frame

Discreet, efficient ladder holder Discreet, efficient ladder holder

Customisable bodywork Customisable bodywork

Bodywork you can maintain yourself Bodywork you can maintain yourself

Up to 5 years warranty Up to 5 years warranty