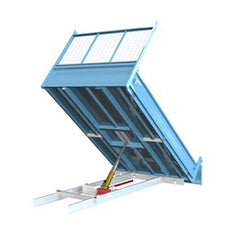

BODYWORK

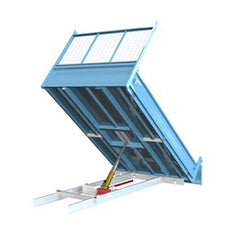

• Tipper platform in high quality aluminium sheet: 5083 H16 thickness 3.5 mm

• Side members in extruded box-sections, thickness 3 mm, height 120 or 140 mm (depending on length) and outer frames in box-sections, thickness 3.5 mm, under the load surface

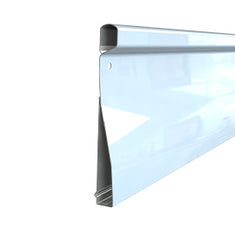

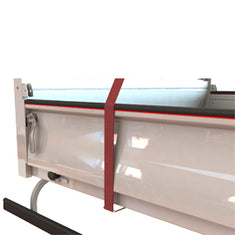

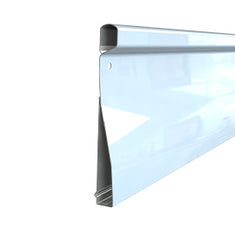

• Sideboards in extruded aluminium profile, height 400 mm (385 mm interior), double wall top and bottom, thickness 2.8mm, single wall, thickness 3.5 mm in the centre, fold-down, removable, interchangeable (right/left)

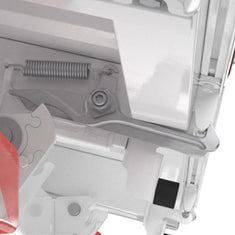

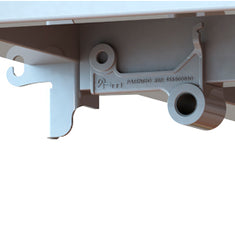

• Locking handle incorporated into the thickness of the sideboards

• Front face, interior usable height 450 mm, double wall top and bottom, thickness 2.6 mm, single wall, thickness 3.5 mm in the centre

• Cab Protect with aluminium grille diameter 5 mm with frame in extruded profiles, removable and without top cap

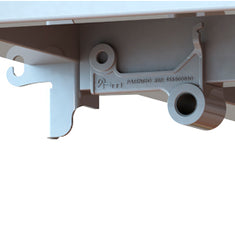

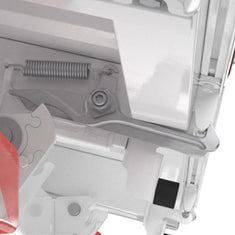

• Aluminium rear door, height 450 mm, double wall top and bottom, thickness 2.8 mm, single wall, thickness 3.5 mm in

the centre, automatic opening by cam of 15° (doorway 520 mm)

• Rubber opening stops on sideboards and rear door

• Rear pillars in galvanised steel, thickness 3 mm, removable, with 12 mm tightening fixing bolt and conical fitting

• Polypropylene fender flares with supports in unwrought aluminium

• Approved aluminium side protection, black powder paint

• Nickel Zinc treated bolts (5 times more resistant than standard galvanising)

• Tipping shaft without lubrication

• Outer frame adapted to lashing

• Short dumping overhang: 250 mm

SUBFRAME

• Aluminium profile tipper, thickness 4.5 to 12 mm

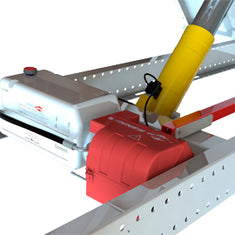

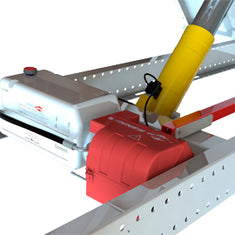

• Tipping by 3 or 4 expansion CYLINDER depending on length (no overhang under the subframe)

• 46° rear tipping angle

• Electrically driven pump unit, 12 or 24 volts depending on the vehicle

• 7-litre tank

• Hydraulic pressure 180 bars

• Wired remote control in cab

SAFETY

• Safety solenoid valve on cylinder

• Circuit breaker

• Safety stand

• Double safety device on the sideboard handles

• Double safety device on the upper door hinges

FINISH

• Shot blasting + 60 μm powder primer + 60 μm powder paint