BODYWORK

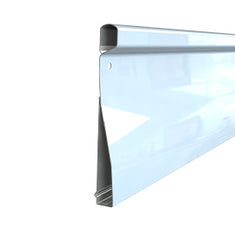

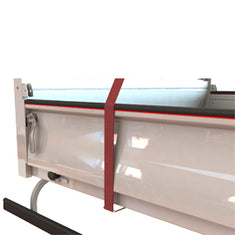

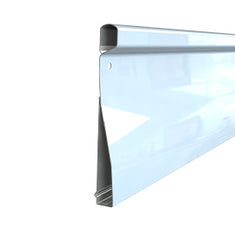

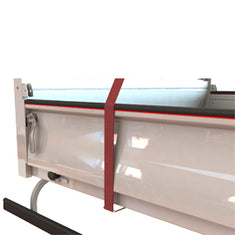

MAX. load capacity: 5 TTipper platform in steel HX500 sheetthickness 3 mmLongitudinal reinforcing spacersSideboards in steel S355, height 350 mm, thickness 2 mm, fold-down, removable, interchangeable (right/left, steel/aluminium)Integrated closing of sideboardsFront face steel S355, height 450 mm, thickness 2 mmGalvanised steel ladder rack, grille (section 4.5 mm), removableRear door in steel S355, height 450 mm, thickness 2 mm, 2 leaves and bottom unhooking by manual unlockingStops on sideboards and rear doorRear pillars in galvanised steel, thickness 3mm, removable, with 12 mm fixing bolt and conical fittingSeals between elements that are not continuously welded2 rear rollers in aluminium fitted on self-lubricating ring (no lubrication)

CRADLE

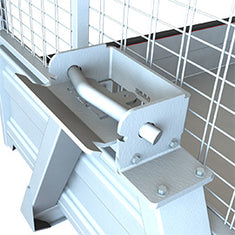

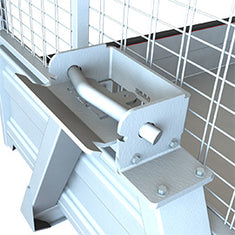

Side members in IPE 140Centre distance 1060Hook height 920 mmGripper diameter 30 welded on structure in tube 120 x 60Exterior locking

SAFETY

Anti-theft to be padlocked

FINISH

DKP sheet + Degreasing + Shot blasting + 60 µm epoxy powder primer + 60 µm powder paint